A Corner Guard is more than a simple protective accessory on the wall of a parking area or workshop. For many facility managers, distributors, and procurement teams, it answers several practical concerns: reducing repair work, preventing small yet costly bumps, and helping drivers stay aware of wall edges in low-light zones. While the structure looks simple on the surface, customers often want to understand what actually shapes performance, durability, and ease of installation before placing an order.

Below are some angles that buyers usually care about, together with clear explanations based on how professional Corner Guard Manufacturers design and produce the product.

1. Corner Guard helps reduce everyday impact damage

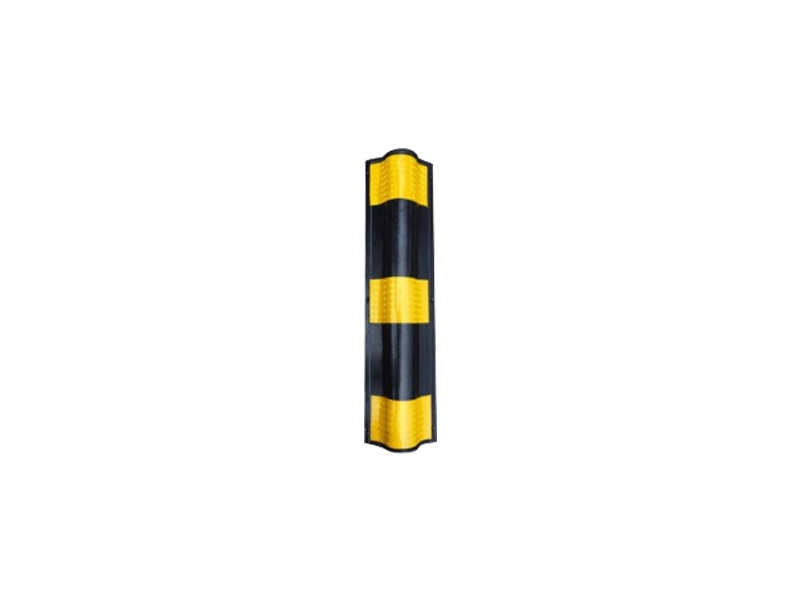

In parking areas, residential driveways, or workshop lanes, a vehicle brushing against a wall corner is a common occurrence. The use of recycled rubber gives the Corner Guard a soft and compressive structure that helps absorb small impacts rather than transfer them directly onto the car's bumper or doors. This softness is the main reason many facility owners prefer rubber over rigid materials.

At the same time, the guard protects the wall corner itself from chips, repeated wear, or cracking. The product acts as a buffer between two surfaces, which appeals to buyers looking for long-term facility maintenance cost control. This practicality is why many projects—from underground garages to toll lanes—include Corner Guard installation early in their layout planning.

2. What visual features help drivers notice the Corner Guard quickly?

A key concern for many buyers is visibility. Corner Guard Manufacturers typically embed bright yellow reflective tapes on the rubber surface, creating a clear contrast between the black base and the warning film. During the day, the yellow segments stand out naturally. At night or in dim areas, the reflective material becomes more noticeable when headlights pass through, helping drivers judge distance and direction more easily.

This visual aid becomes especially valuable in tight parking spaces, indoor garages, and loading areas where movement is slow but frequent. Buyers often mention that clear visibility reduces hesitation among drivers and supports smoother traffic flow through narrow paths.

3. How flexible is the installation process across different facility types?

Customers purchasing for industrial or commercial sites want products that do not require complex tools or specialized teams. A Corner Guard is typically designed for fast installation: drill a simple hole in the wall surface, insert expansion screws, and secure the product tightly. This straightforward method lets maintenance teams complete multiple installations in a short timeframe.

Because the Corner Guard is lightweight and adaptable to various surface shapes, buyers can use it on parking pillars, loading docks, gas station walls, or the sides of home garage entrances. Many users also choose to install the lower edge around 20 cm above the ground, a commonly used height that aligns well with vehicle bumper levels.

4. How do Corner Guard Manufacturers address durability expectations?

Buyers expect long service life, especially in high-traffic environments. Manufacturers use recycled rubber not only as a cost-efficient material but also for its resistance to compression and deformation. The material maintains shape even after repeated contact, which is important in facilities where vehicles move in and out throughout the day.

Another area buyers often examine is long-term visibility. Quality reflective surfaces retain brightness after exposure to moisture, dust, or temperature changes. Durable adhesion of the yellow tape helps the product keep its warning function over time, making it suited for both indoor and semi-outdoor installations.

A Corner Guard may look like a small part of a facility, but it supports smoother vehicle movement, reduces building maintenance, and gives drivers clearer visual guidance. For distributors or project contractors, working with experienced Corner Guard Manufacturers helps maintain consistent quality across batches and ensures the product performs reliably in real conditions.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语.jpg)