As urban infrastructure continues to evolve to meet accessibility, safety, and durability standards, rubber kerb ramps have emerged as a practical solution for overcoming elevation differences in both public and private spaces. Whether used in driveways, loading zones, industrial facilities, or pedestrian pathways, the role of the rubber kerb ramp has expanded significantly. One of the important developments in recent years is the improvement of non-slip technology, which has made rubber kerb ramps safer and more effective in various weather and surface conditions.

Traditionally, rubber kerb ramps have been valued for their portability, ease of installation, and impact absorption. However, earlier versions sometimes lacked the necessary grip to ensure stability, especially in wet, oily, or icy environments. Slippery surfaces can pose a risk to both pedestrians and vehicles, particularly when ramps are installed at steeper angles or in high-traffic areas. As a result, manufacturers have invested in research and design innovations to improve the non-slip performance of the rubber kerb ramp.

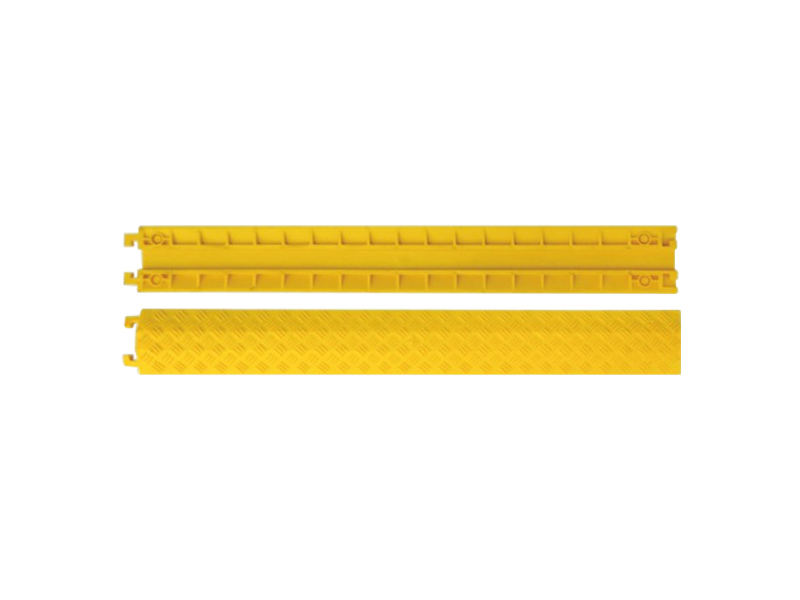

One of the major advancements has been the use of textured tread surfaces molded directly into the body of the rubber kerb ramp. These patterns—ranging from cross-hatch to raised dot textures—create additional friction between the ramp and tires, shoes, or mobility aids. The added grip helps reduce the risk of slipping during use, even under wet conditions. The surface textures are engineered to maintain their integrity over time, resisting flattening or wear that could compromise performance.

Another improvement in rubber kerb ramp technology involves the incorporation of high-friction rubber compounds. These upgraded materials increase the natural grip of the ramp, especially when used on smooth concrete or asphalt surfaces. Many manufacturers are now blending recycled rubber with specialized polymers to enhance traction without sacrificing flexibility or load-bearing capacity. This innovation makes modern rubber kerb ramps suitable for both light pedestrian use and heavy-duty vehicle access.

Edge design has also played a role in improving non-slip functionality. Tapered edges and beveled sides not only aid in smoother transitions but also reduce the chance of tripping or sudden skidding. In some designs, rubber kerb ramps now feature integrated drainage channels, which help direct water away from the surface, minimizing pooling and slippage. These channels are particularly useful in outdoor applications where exposure to rain and snow is frequent.

The application of reflective elements is another added safety feature. While not directly linked to slip resistance, reflective strips or inlaid markings improve visibility in low-light settings, reducing the likelihood of missteps or sudden stops. Combined with non-slip surfaces, these features make the rubber kerb ramp a much safer option in both residential and commercial installations.

One of the key markets benefiting from these advancements is healthcare and elder care. Facilities with mobility-impaired individuals require consistent, safe access across level changes. The latest rubber kerb ramps, with enhanced grip and shock absorption, provide a reliable solution for wheelchairs, scooters, and walking aids. The stability provided by improved non-slip surfaces allows users to move with greater confidence and less assistance.

Warehouses and logistics centers are also adopting non-slip rubber kerb ramps to ensure the safe transfer of goods and equipment across thresholds, loading docks, or uneven ground. Forklifts and pallet jacks require steady traction to prevent tipping or slipping, and the enhanced grip technology in newer ramp models directly supports this need.

In summary, the evolution of non-slip technology in rubber kerb ramps reflects a broader commitment to safety and functionality. From material innovation to improved tread design and integrated drainage systems, each advancement contributes to more reliable performance. As more industries and homeowners prioritize safe, accessible spaces, the continued improvement of rubber kerb ramp technology ensures these tools remain effective and dependable across a range of real-world environments.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语