Every day, millions of people walk or drive past a line of bright orange cones without thinking twice. Yet behind those simple, cone-shaped markers is a thoughtful design process that blends visibility, flexibility, and practicality. A Traffic Cones Factory plays an unseen but crucial role in keeping roads, work areas, and public spaces organized and safe for everyone.

1. The Real Role of Traffic Cones

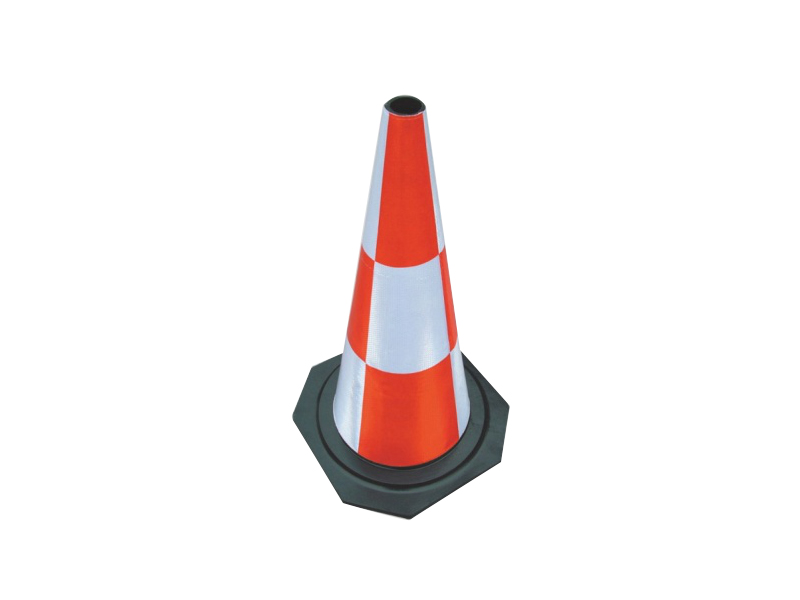

A Traffic Cone is more than just a bright object on the road. It's a temporary guide, signaling caution, direction, or restriction. On highways, it divides lanes during maintenance; in parking areas, it separates vehicles and pedestrians; at festivals or sports events, it guides people smoothly through crowded zones.

Because of their flexibility and strength, Traffic Cones are trusted for countless uses beyond traffic management. They are often placed near aircraft on airport ramps to warn ground crews of engine zones. They can even be flipped upside down as a funnel or a quick stand during maintenance tasks. Some creative users even employ them for training drills or decoration in sports facilities.

2. What Makes a Good Traffic Cone

The success of a Traffic Cones Factory depends on material quality and production precision. many cones are made of durable PVC or rubber, designed to endure collisions, pressure, and long outdoor exposure. Even when run over by a car, the cone quickly regains its shape instead of cracking. This flexibility makes it a cost-efficient and reliable option for long-term use.

Another essential feature is reflectivity. Each Traffic Cone is wrapped with high-intensity reflective bands-fluorescent orange for daytime visibility and silver-gray for nighttime reflection. Whether it's raining, foggy, or dark, drivers can spot these signals from a distance, giving them time to react and adjust safely.

In addition to durability, traffic cones are designed for convenience. Their stackable shape saves space during transport and storage, making them easy to move and deploy in any situation.

3. What Happens Inside a Traffic Cone Factory

Inside a Traffic Cones Factory, production follows a well-organized process that balances efficiency and consistency. Raw materials are mixed and shaped under high temperatures to achieve elasticity. After molding, each cone is cooled, checked for surface finish, and fitted with reflective tape.

Factories also adapt designs according to user needs-some require heavier bases for wind resistance, while others prefer lighter cones for quick setup at temporary events. The goal is to create reliable markers that meet different environments, from hot highways to icy construction zones.

4. The Everyday Impact of Reliable Traffic Cones

Though small, Traffic Cones make daily movement smoother and safer. They organize temporary construction work, help people avoid hazards, and maintain a sense of order in busy or changing environments. For event planners, they help create structured zones without permanent barriers. City workers mark off restricted areas quickly and clearly.

A Traffic Cone may seem like a simple object, but its impact reaches far beyond its size. Behind every cone is the innovation and craftsmanship of a Traffic Cones Factory that understands how small design details-like flexibility, reflectivity, and color-can make a real difference on the road. These humble markers quietly keep our streets and workspaces running smoothly, one bright orange signal at a time.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语