Vehicle movement does not always happen when driving. Parking on slopes, loading zones, and roadside repair areas often brings unexpected rolling risks. A Wheel Chock is designed to sit directly against the tire, acting as a physical stop to limit forward or backward motion. This simple structure plays a practical role across logistics yards, workshops, and roadside service scenarios.

Unlike complex mechanical systems, a wheel chock works without power or adjustment. Its effectiveness depends on material, shape, and proper placement rather than added components.

Common Situations Where Wheel Chocks Are Used

Wheel chocks are often used during parking, maintenance, and temporary stops. In loading and unloading operations, vehicles may remain stationary for extended periods. A wheel chock helps keep the vehicle in position while goods are moved.

During roadside repairs, placing a chock under the wheel helps reduce unintended movement caused by uneven surfaces. On slopes, chocks are positioned downhill from the vehicle's center of gravity to counter rolling force. These usage habits are consistent across trucks, trailers, vans, RVs, and passenger vehicles.

Material Structure and Performance in Daily Use

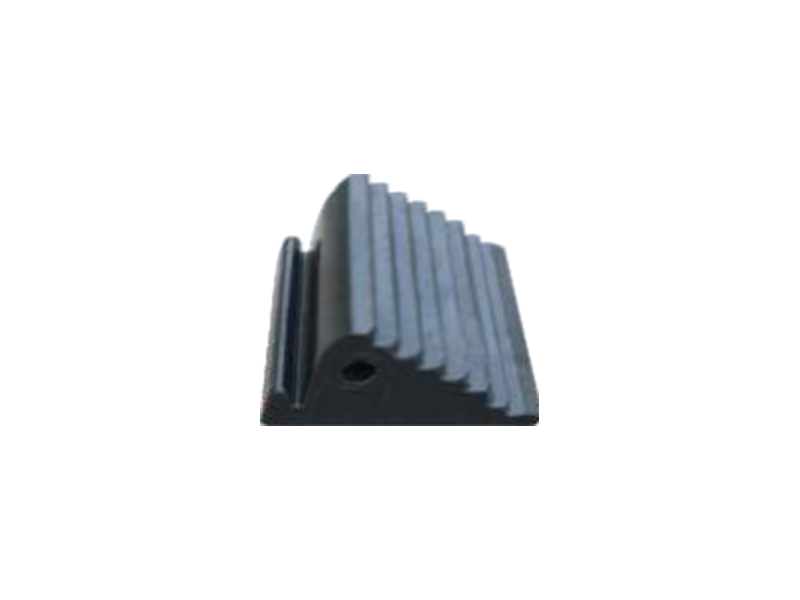

Rubber wheel chocks are widely used because of their balance between weight and flexibility. Made from recycled rubber through high-pressure vulcanization, they resist deformation under repeated contact with tires. The surface texture provides strong friction against both the ground and the tire tread.

Many designs use a partially triangular profile. This shape allows the chock to sit closely against the tire while maintaining surface contact with the ground. Oil-resistant and slip-resistant properties help the chock perform consistently in workshops, parking areas, and outdoor environments.

Why Manufacturing Process Matters

A Wheel Chock Factory with stable production control influences how the product behaves in real conditions. Factors such as rubber compound ratio, molding pressure, and curing temperature affect strength and surface finish. Clean trimming and uniform density support consistent placement and handling.

Zhejiang Luba Traffic Technology Co., Ltd., established in 2001, operates as a professional Rubber Wheel Chock Factory in China. Located in Zhejiang Province, about 100 kilometers from Ningbo Port and the airport, the factory supports efficient logistics for export markets. With an annual production capacity exceeding 20,000 tons, it develops and manufactures rubber wheel chocks according to drawings or samples. Products meet international standards and are supplied to regions including the United States, Spain, Italy, Australia, South Korea, and Chile.

Placement Guidelines That Influence Results

Correct placement is as important as product design. A Wheel Chock should be centered and aligned at a right angle to the tire. It needs to sit firmly against the tire tread rather than loosely touching the sidewall. Using chocks in pairs helps balance holding force, especially on uneven ground.

On downhill surfaces, chocks are placed in front of the wheels. On uphill slopes, they are positioned behind the rear wheels. On flat ground, placing chocks both in front of and behind individual wheels supports stability during long stops.

A Wheel Chock remains a practical tool because of its direct function and simple structure. When produced by an experienced Wheel Chock Factory and used with correct placement, it supports controlled parking and stationary operations across many working environments.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语